BAND SAW SBW-3501B

BAND SAW SBW-3501B

TECHNICAL DATA :

Motor : 3/4HP (0.55 Kw)

Table Size (L x W) : 14" x 14" (356 x 356 mm)

Wheel Size : 14" (356 mm)

Cutting Height : 8" (200 mm)

Max. Cutting Width : 13 3/8" (339 mm)

Max. Cutting(Rip Fence) : 11 3/4" (300 mm)

Saw Blade Length : 100 3/4" (2562 mm)

Saw Blade Width : 1/8" to 3/4" (3 mm to 19 mm) (Standard 3/8")

Saw Blade Speed : 3100 SFPM (945 m/min)

Table Tilting : Left 10° / Right 45° 20° (CE)

Table Height from Ground : 42" (1066 mm)

Dust Chute Diameter : ø4" (100 mm) x 1

Machine Size (L x W x H) : 17-1/2" x 24" x 69" (445 x 610 x 1753 mm)

BAND SAW SBW-4300, SBW-4800 & SBW-5300

BAND SAW SBW-4300, SBW-4800 & SBW-5300

TECHNICAL DATA :

Model : SBW-4300 / SBW-4800 / SBW-5300

Motor : 2 HP (1.5 Kw) / 2 HP (1.5 Kw) / 2 HP, 3 HP (1.5 Kw, 2.25 Kw)

Wheel Size : 17" (430 mm) / 19" (480 mm) / 21" (530 mm)

Table Size : 17" x 17" (430 x 430 mm) / 19" x 19" (480 x 480 mm) / 21" x 21" (530 x 530 mm)

Cutting Height : 12" (300 mm) / 12" (300 mm) / 12" (300 mm)

Max. Cutting Width : 16 1/4" (410 mm) / 18 1/4" (462 mm) / 20 1/4" (514 mm)

Max. Cutting (Rip Fence) : 14 5/8" (370 mm) / 16 5/8" (422 mm) / 18 5/8" (474 mm)

Saw Blade Length : 131 1/2" (3340 mm) / 143" (3632 mm) / 152" (3861 mm)

Saw Blade Width : 3/8" to 1" (9.5 to 25.4 mm) (Standard 1/2") / 3/8" to 1" (9.5 to 25.4 mm) (Standard 3/4") / 1/8" to 1" (9.5 to 25.4 mm) (Standard 3/4")

Saw Blade Speed : (3300/1600 SFPM)(1000/490 M/min) / (3700/1700 SFPM)(1130/520 M/min) / (4000/1900 SFPM)(1220/580 M/min)

Table Tilting : Left 10° / Right 45° 20°(CE) / Left 10° / Right 45° 20°(CE) / Left 10° / Right 45° 20°(CE)

Table Height from Ground : 37 1/2" (950 mm) / 37 1/2" (950 mm) / 37 1/2" (950 mm)

Dust Chute Diameter : Ø4" (100 mm)x2 / Ø4" (100 mm)x2 / Ø4" (100 mm)x2

Machine Size : (L X W X H) 32" x 26" x 74" (820 x 670 x 1880 mm) / 36" x 30" x 78" (920 x 770 x 1990 mm) / 40" x 31" x 80" (1020 x 790 x 2040 mm)

BAND SAW SBW-5300H & SBW-6300H

BAND SAW SBW-5300H & SBW-6300H

TECHNICAL DATA :

Model : SBW-5300H / SBW-6300H

Motor : 3 HP / 5 HP, 3 HP (2.25 Kw / 3.75 Kw) / 5 HP, 3 HP (3.75 Kw)

Table Size (L x W x H) : 29.6" x 20.8" x 2" (750 x 530 x 50 mm) / 33 1/2 x 23 5/8 x 2" (850 x 600 x 50 mm)

Cast Iron Wheel Size : 21" (530 mm) / 25" (630 mm)

Cutting Height : 14" (350 mm) / 16" (400 mm)

Max. Cutting Width(without fence) : 20" (510 mm) / 24 1/2" (622 mm)

Max. Cutting Width (with fence) : 18 1/4" (465 mm) / 22 1/2" (570 mm)

Saw Blade Length : 165" (4190 mm) / 181" (4600 mm)

Saw Blade Width : 1/4" - 1 3/8" (6 - 35 mm) Standard 1"(Standard 25 mm) / 1/4" - 1 1/2" (6 - 38 mm) Standard 1"(Standard 25 mm)

Saw Blade Speed : 1370 M/min (4500 FPM) Single Speed (820 rpm) / 1615 M/min (5300 FPM) Single Speed (820 rpm)

Table Tilting : 45° (20° CE) / 45° (R) (20° CE)

Table Height : 35 1/2" (900 mm) / 33" (830 mm)

Dust Chute : 4" x 2 pcs (100 mm x 2 pcs) / 4" x 2 pcs (100 mm x 2 pcs)

Braking System : Foot Pedal + Micro Switch(Electronic Braking Switch System) / Foot Pedal + Micro Switch(Electronic Braking Switch System)

Blade Guide : Ball Bearing (European Roller Disk Type) / Ball Bearing (European Roller Disk Type)

Driving Belt : A type x 2 grooves / A type x 2 grooves

Cast Iron Fence : 1 1/4"(W) x 3 5/8"(H) (30(w) x 90(H)mm) / 1 1/4"(W) x 3 5/8"(H) (30(w) x 90(H)mm)

Sound Rating : 63-70 db / 63-70 db

Machine Size (L x W x H) : 39.4" x 28.3" x 78" (1002 x 727 x 1982 mm) / 47" x 29 1/2" x 81" (1190 x 750 x 2060 mm)

SE 65/5T

SE 65/5T

TECHNICAL DATA :

Center distance between each chuck. (mm) : 32

Max thickness of the panels (mm) : 80

Max boring depth (mm) : 70

Chucks rotation speed (rpm) : 2800

Chucks of the horizontal unit (n°) : 21

Chucks of the vertical units (n°) : 2x11 + 2x11

Min-max distance between vertical heads(mm) : 150-1100

Motors power. Kw(HP) : 1x 1,5(2) / 4x 1,1(1,5)

SE 21

SE 21

TECHNICAL DATA :

Chucks (n.) : 21

Center distance between chucks (mm) : 32

Center distance between first and last chuck (mm) : 640

Max thickness of the panel (mm) : 80

Max drilling depth (mm) : 100

Working table size (mm) : 860x400

Max size of the piece to drill (mm) : 850x3000

Chuck revolution (rpm) : 2800

Motor power. Kw (HP) : 1,5 (2)

F 530

F 530

TECHNICAL DATA :

Working width (mm) : 530

Table length (mm) : 2850

In-feed table length (mm) : 1570

Out-feed table length (mm) : 1280

Tables height (mm) : 860

Cutter head diameter (mm) : 120

Cutter head speed (rpm) : 5000

Number of cutter head knifes : 4

Motor power (Hp) : 4

RS.53S

RS.53S

Technical Data:

Working width : 530 mm

Max. working weight : 300 mm

Min. working weight : 3 mm

Number of knives : 4

Dimension of knives : 530X35X3 mm

Cutter head speed : 4800 rpm

Feeding speed : 4/16 m/min

Motor power : 5,5 hp (4 kW)

PANEL SAW D405A

PANEL SAW D405A

TECHNICAL DATA :

Sliding table dimension : 3,200 x 395 mm

Cast Iron table : 548 x 896 mm

Extension table (rear) : 952 x 896 mm

Extension table (front) : 830 x 320 mm

Table size : 1500 x 1726 mm

Round rail : Φ 50 mm

Main saw blade : Φ 400 (16")

Main saw bore : Φ 30 mm

Max. Cutting height at 90°(355 mm) : 105

Max. Cutting height at 45°(355 mm) : 70

Main motor power 7.5 HP (5.5 Kw) : 3PH

Main blade speed : 3,000/ 4,000/ 5,000 rpm

Scoring saw blade : Φ 120

Scoring saw blade bore : Φ 20 mm

Scoring blade motor power : 1 HP (0.75 kw)

Scoring blade speed : 8,000 rpm

Cuting width : 1,300 mm

Main saw blade tilting adjustment : Manual(0°~45°)

Main saw height adjustment : Motorized

Scoring saw adjustment : Motorized

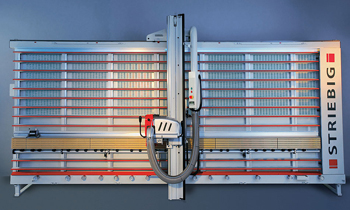

COMPACT 5207

COMPACT 5207

TECHNICAL DATA :

Weight of the saw : 910 Kg

Cutting depth : 60 mm

Saw motor rating : 3.9 Kw

Saw blade diameter : 250 mm

Saw blade bore : 30 mm

2 extraction connection : 100 mm

Wattage : 4.8 Kw

K 5-400

K 5-400

TECHNICAL DATA :

Planning working table sizes (mm) : 1850 x 410

Thicknessing working table sizes (mm) : 800 x 40

Saw and spindle moulder working table sizes (mm) : 1400 x 550

Diam. of the spindle with 3 knives (mm) : 30

Spindle rotation speed : 4260

Max. thicknessing working height (mm) : 225

Max depth of cut : 5

Diameter of the cutter block : 100

Number of cutters : 4

Feeding speed, m/min : 6/12

Motor power, Hp : 4

EDGE BANDER MAX330

EDGE BANDER MAX330

TECHNICAL DATA :

PLC control, with separate controls for each unit. The frame is constructed from solid steel, making it both stable, and reliable : The MAX 330 can apply straight edges to panels with an automatic feed, and spreads glue directly onto wood or plastic edges in coils up to 3mm thick and strips up to 4 mm thick.

Automatic stand-by temperature : The electronic temperature control automatically switches to standby mode when not in use.

Glue Pot : The Teflon-coated glue pot has a capacity of 1.1 kgs, and includes 5 heating elements, as well as a glue temperature regulator, with automatic stand-by.

Trimming cut-off for front/rear edge express : The working cycle is controlled by PLC, with separate controls for each unit.

Dust device : The high•efficiency dust port allows dust to be collected directly under the table, for a clean work environment.

Flush with trimmers copying pads : Copying disc, numerical indicators for adjustments, combined TCT cutters beveled/radius

Overhead protection guard : The guard can be lifted, to allow for checking on small edge banding jobs.

Panel thickness ˚ (mm) : 12 •45 mm (numerical panel thickness indicator)

Edge thickness˚ (mm) : Min•Max 0.4•3.0 mm/up to 4.0 mm for strips

Feeding motor : 0.37 kw (automatic panel belt feeder). The large working table with 11 adjustable rollers is capable of supporting large panels. Includes an extensible support for large panels.

Glue & edge : 0.18 kw

Heating elements : 5 pcs with 1.2 kw

Heating In-feed fence : 0.32 kw (In cases where the panel. may be too wet due to poor weather conditions, this feature helps dry it, in order to achieve a good finish)

End trimming motor : 0.18 kw 80 mm (Automatic front/rear cut off trimming, and flush trimming and buffing on both sides of the work piece)

Flush trimming motor : 0.56 kw

Buffing Unit : 0.12 kw*2 - 120 mm - 3000 RPM (Cleans and polishes edges)

Cutter : Cutter-block with disposable cutters TCT beveled/radius 10,000 RPM. 75 mm radius 2 mm/15 ' bevel (optional)

Total power installed : 3.2 kw

EDGE BANDER MAX340

EDGE BANDER MAX340

TECHNICAL DATA :

Feeding speed : 9M/min

Panel Thickness : 8-45 mm

Edge Thickness : 0.4 - 3 mm

Mini Panel Width : 100 mm

Mini Panel Length : 210 mm

Working Table Height : 850 mm

Extensible Support Width : 560 mm

Extractor Connector Ø in mm : Ø5"

Motor : 5.5 Kw

Overall Size : 3220 x 1485 x 1370 mm

Weight, kg (with standard equipment) : 510kgs/558kgs (N.W./G.W.)

Packing Size : 2290 x 720 x 1360 mm

Container Qty : (20'/40') 8 sets/ 16 sets

Up/Down : 12000rpm

Front/Rear : 12000rpm

Buffing : 3000rpm

POWER (KW)OF EACH MOTOR

Feeding Motor : 0.75 (Kw)

Glue Spindle Motor : 0.18 (Kw)

Front/Rear Trimming Motor : 0.22 (Kw)

Upper Trimming Motor : 0.37 (Kw)

Lower Trimming Motor : 0.37 (Kw)

Upper Buffing Motor : 3ph-0.12 (Kw); 1ph-0.18(Kw)

Lower Buffing Motor : 3ph-0.12 (Kw); 1ph-0.18(Kw)

Pre-heating : 0.4 (Kw)

Glue Pot Heating : 1.315 (Kw)

BS 940 BAND SAW

BS 940 BAND SAW

TECHNICAL DATA :

Flywheels diameter mm. : 940

Flywheel speeds r.p.m. : 550

Motor power HP (kW) : 7,5 (5,5)

Max. cutting height mm. : 560

Cutting width mm. : 910

Table sizes mm. : 820 x 1300

Blade length mm. min. : 6590 max. 6710

Overall dimensions mm.˚ (mm) : 1550 x 920 x 2900

Packing dimensions mm.˚ (mm) : 2990 x 670 x 1470

Net weight kg. : 700

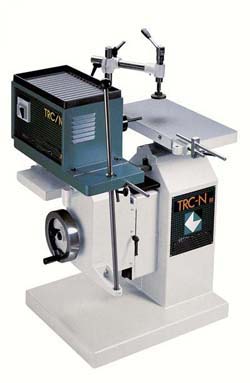

TRC/N MORTISING MACHINE WITH FIXED TABLE

TRC/N MORTISING MACHINE WITH FIXED TABLE

TECHNICAL DATA :

Longitudinal stroke of the head : 240 mm.

Transverse stroke of the head : 180 mm.

Vertical stroke of the head TRC/N fixed table : 160 mm.

Vertical stroke of the head TRC/N tilting table : 140 mm.

Vertical stroke of the head TRC/N turning table : 140 mm.

Working table sizes : 565 x 315 mm.

Westcott chuck : 0-20 mm.

Chuck rotation speed : 3000 r.p.m.

Motor power : 2 hp (1,5 kw)

Net weight : 260 kg.

Noise level according to DIN 45635/1600 : 66,9 db (a)

'CE' Standards

MC 60

MC 60

TECHNICAL DATA :

Chain motor power : 3 HP

Motor R.P.M. : 2800 g./min

Motor shaft diameter : 16 mm

Vertical spindles motor power : 0.5 HP

Horizontal spindles motor power - 1 HP work table size : 600 x 110 mm

Overall dimensions : 1000 x 800 x 210

Weight : 500 kg

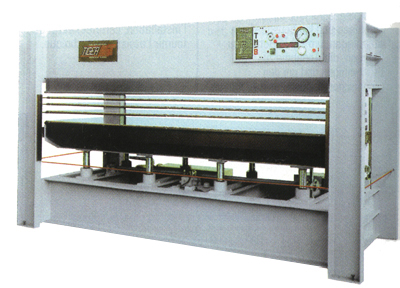

GAMMA/90

GAMMA/90

Clamping press for windows and doors. Corpus press semiautomatic and automatic. Hot and cold, single and multi-daylights for the production of panels overlaid with veneer, HPL, LPL, decorative papers. Embossing presses for bending massive wood. Membrane presses to glue on the shape panels PVC, PPL, veneer. Automatic pressing line for panels.

MOD. R/3 130

MOD. R/3 130

TECHNICAL DATA :

Maximum working thickness mm. : 70

Feeding speed mtpm : 20

Nr. 2 spreading roller diam. mm. : 185

Motorgear power Kw. : 0,37

Nr. 2 gluw dosing blades with micrometric adjustment

Safety screens with electric interlock

AM - 70 / N

AM - 70 / N

TECHNICAL DATA :

Model : GM 104S / GM 104E

Min/max pitch of saws and belts teeth (mm) : 3 – 25 / 3 - 25

Max blade width (mm) : 50 / 50

Min/max diameter of the panel saw (mm) : 110-600 / 110-600

Grinding motor power. KW (HP) : 0,20 / 0,20

Motor power. KW (HP) : 0,20 / 0,20

Teeth sharpened per min. (n°) : 70 / 70

Grindstone diameter (mm) : 152 / 152

G 60 ROUTER WITH TILTING HEAD

G 60 ROUTER WITH TILTING HEAD

TECHNICAL DATA :

Belt transmission

Pneumatic control

Chuck MK2 complete with 3 collets: 6-8-9,5

Self-braking motor

Working table sizes : 800 x 600 mm.

Chuck rotation speed : 9000-18000 r.p.m.

Motor power G 60 : 2/3 hp (1,5/2,2 kw)

Motor power G 80 - G 90 : 3/4 hp (2,2/3 kw)

Net weight G 60 : 290 kg.

Net weight G 80 : 360 kg.

Net weight G 90 : 410 kg.

'CE' standards

T.120

T.120

TECHNICAL DATA :

Table dimensions : 1100 x 800 mm

Max. profiling tool diameter : 250 mm

Max. tenoning tool diameter : 320 mm

Spindle speed : 3000/4500/6000/8000 rpm

Spindle motor power : 4 hp (3 kW)

CONCEPT 1350/3

CONCEPT 1350/3

TECHNICAL DATA :

Usable working width : 1350 mm

Min/max working height on floating table : 3-160 mm

Belt width and length : 1380 x 2200 mm

Motor power on the belt : 7,5Kw (10 HP)

Feed belt motor power : 0,75/1,1 Kw (1/1,5 HP)

Air consumption : 90 Nl/min

Working pressure : 6 bar

Air consumption : 9000 mc/h

Feed speed : 4,5/9 m/min

TS 100 P

TS 100 P

TECHNICAL DATA :

Cutting length (mm) : 4300

Space needed by the main saw body (mm) : 2860

Cutting height (mm) : 90-60

Main blade motor (HP) : 15

Main blade diameter/hole (mm) : 350 (355)/75

Saw-carriage forward speed. (m/min) : 3/60

Saw-carriage return speed. (m/min) : 60/120

Pusher speed / positioner (m/min) : 2/40

Pusher return speed. (m/min) : 40/60

Dust extraction outlets (mm) : 4@120

Weight (kg) : 30

1st and 2nd rollers dia (mm) : 5000

SMART 30

SMART 30

TECHNICAL DATA :

X-Y-Z axes strokes (mm) : 3540 -1780 -430

Max thickness for panel feeding (mm) :120

Vectorial speed (mt/m) : 90

Spindle rotation (rpm) : 500 / 24000

Pggy back tool change : N° B

Inverter power (Kw) : 11/15

Vacuum pump capacity (mc/h) : 150

Max absorbed power (Kw) : 35

Air working pressure (bar) : 7

Air circuit connection coupling (G) : 3/8"

NT5 A COMPACT AND FAST EDGE BANDER

NT5 A COMPACT AND FAST EDGE BANDER

TECHNICAL DATA :

Working height : 8-45 mm

Thickness of edging in rolls : 0,4-3 mm

Max. thickness of edging in strips : 5 mm

Panel feed speed : 11 n/min

PR.230-5

PR.230-5

TECHNICAL DATA :

Number of operating spindles : 5

Tool diameter on first spindle : 120 mm

Min. diameter 2nd/3rd/4th/5th spindle : 100 mm

Max. diameter 2nd/3rd/4th/5th spindle : 180 mm

Horizontal spindles length : 240 mm

Vertical spindles length : 130 mm

Feeding speed : 6/12 m/min

Feed unit motor power : 0,9/1,5 kW

F1B 80-16

F1B 80-16

Tool for "80" staples with length from 6 to 16 mm

Height : 157

Length : 218

Width : 42

Min/Max Pressure : 4/7

Weight : 0,78

Magazine Capacity : 140

Air Consumption : 0,37

Actuation Mode : SAFETY: MANUAL

◆ Long and narrow nose design: excellent job visibility

◆ Rubber comfort grip: non-slip handling and reduction of vibrations and fatigue

◆ One hand latch: fast reloading and reduced downtime

◆ Reversible bumper: high durability

◆ Rear exhaust with muffler: avoids lubricant from falling onto work surface

◆ Bottom loading magazine: protects internal parts (reduced maintenance)

F1B 80-16 LN.50

F1B 80-16 LN.50

Tool with 50 mm long nose for "80" staples with length from 6 to 16 mm

Height : 205

Length : 218

Width : 42

Min/Max Pressure : 4/7

Weight : 0,84

Magazine Capacity : 140

Air Consumption : 0,5

Actuation Mode : SAFETY: MANUAL

◆ Rubber comfort grip: non-slip handling and reduction of vibrations and fatigue

◆ One hand latch: fast reloading and reduced downtime

◆ Reversible bumper: high durability

◆ Rear exhaust with muffler: avoids lubricant from falling onto work surface

◆ Bottom loading magazine: protects internal parts (reduced maintenance)

F45C G-55B W.S.A.

F45C G-55B W.S.A.

Tool for "G" staples with length from 25 to 55 mm

Height : 316

Length : 365

Width : 90

Min/Max Pressure : 5/8

Weight : 2,4

Magazine Capacity : 160

Air Consumption : 1,39

Actuation Mode : SINGLE SHOT/CONTACT TRIP

◆ Adjustable exhaust cover: allows air to be directed away from the operator and the material being fastened

◆ Rubber comfort grip: non-slip handling and reduction of vibrations and fatigue

◆ Patented sequential fire / bump fire (CT/SS) device: the safest in the world

◆ Driver threaded into the piston for a better resistance

◆ Tool-less jam clearing mechanism provides easy access to nose if staple jams

◆ Adjustable safety to control countersink consistently

F3C FN-50A

F3C FN-50A

Tool for FN brads, wire 1,35 x 1,60 mm with length from 15 to 50 mm

Height : 245

Length : 290

Width : 70

Min/Max Pressure : 5/7

Weight : 1,71

Magazine Capacity : 100

Air Consumption : 0,85

Actuation Mode : CONTACT TRIP, SINGLE SEQUENTIAL ACTUATION ON REQUE

◆ Rubber comfort grip: reduces vibrations and minimizes worker’s fatigue

◆ No-mar tip: avoids marring of soft wood

◆ Slim nose: precise nailing

◆ Peep-hole for viewing brads: reduces the incidence of dry-fire

◆ Driver threaded into the piston for a better resistance

◆ Rear safety: better visibility of the work surface

◆ Tool available also in a plastic case

F21P GN-31A

F21P GN-31A

Light bradder for GN brads, wire 1,00 x 1,27 mm with several lengths from 13 to 31 mm

Height : 187

Length : 257

Width : 49

Min/Max Pressure : 4/7

Weight : 1,15

Magazine Capacity : 105

Air Consumption : 0,36

Actuation Mode : CONTACT TRIP

◆ Reversible bumper: high durability

◆ No-mar tip: avoids marring of soft wood

◆ Peep-hole for viewing brads: reduces the incidence of dry-fire

◆ Quick clear device by using comfortable rear latch. No keys needed

F6AC RHN20-100A

F6AC RHN20-100A

Tool for full head 20° plastic strip nails with length from 50 to 100 mm

Height : 380

Length : 545

Width : 105

Min/Max Pressure : 5/8

Weight : 3,93

Magazine Capacity : 62

Air Consumption : 1,92

Actuation Mode :SINGLE SHOT/CONTACT TRIP

◆ Rubber comfort grip: reduction of vibrations and fatigue

◆ Extruded aluminum alloy magazine: holds three strips of nails

◆ Tool-free depth of drive adjustment to countersink or flush drive nails

◆ No-mar tip storable in the canister: ensures undamaged wood surfaces

◆ Two finger trigger for greater firing control

◆ Body and cap in high strength magnesium alloy: balance and ease of handling

◆ Patented sequential fire / bump fire (CT/SS) device: the safest in the world

◆ Toe nailing work contacting element: excellent gripping of wood

F21P GA-18/31A

F21P GA-18/31A

Tool for "GA" pins with length from 12 to 18 mm

Height : 182

Length : 226

Width : 49

Min/Max Pressure : 4/7

Weight : 1,02

Magazine Capacity : 100

Air Consumption : 0,36

Actuation Mode :CONTACT TRIP

◆ Reversible bumper: high durability

◆ Peep-hole for viewing brads: reduces the incidence of dry-fire

◆ Steel driver blade: rugged and long lasting

◆ Quick clear by opening the magazine, no key required

◆ Steel driver blade: rugged and long lasting

F1B 80-25 PLIER

F1B 80-25 PLIER

Bedding plier tool for "80" staples with length from 12 to 25 mm

Height : 327

Length : 380

Width : 75

Min/Max Pressure : 4/7

Weight : 2,22

Magazine Capacity : 310

Air Consumption : -

Actuation Mode :SAFETY: MANUAL

◆ Large magazine: it holds 310 staples

◆ Adjustable jaw opening by simply turning the screw on the top of the tool (from 50 to 70 mm)

◆ Rubber comfort grip: non-slip handling and reduction of vibrations and fatigue

F3C ATW-38

F3C ATW-38

Tool for "ATW" staples with length from 19 to 38 mm

Height : 231

Length : 343

Width : 70

Min/Max Pressure : 5/7

Weight : 2,2

Magazine Capacity : 155

Air Consumption : 1,17

Actuation Mode :CONTACT TRIP

◆ Driver threaded into the piston for a better resistance

◆ Rubber comfort grip: non-slip handling and reduction of vibrations and fatigue

◆ Two finger trigger: provides less fatigue and more control