SATAjet® 4000 B HVLP

SATAjet® 4000 B HVLP

Lighter, improved handling, higher precision: the ergonomic design.

SATAjet 4000 B, due to its ergonomically formed gun handle, fits like a glove. We have reduced its weight by 15% compared to the previous model. In addition, we have lowered the center of gravity of the spray gun by a great deal for the benefit of the painter.

Improved control elements.

With just a quarter turn of the innovative round/ flat spray control, the spray fan can be precisely adapted to the shape of the object. For safer and even more comfortable paint application.With just a quarter turn of the innovative round/ flat spray control, the spray fan can be precisely adapted to the shape of the object. For safer and even more comfortable paint application.

Softer: the nozzle concept

The new nozzle concept of the SATAjet 4000 B has been enhanced to meet the requirements of modern paint systems. Providing a uniform and perfectly shaped spray fan, the material lays down softly and evenly. The noise level has been reduced by up to 50%. Highest color match precision, high gloss and uniform paint distribution ensure brilliant finishes at rapid application speed. The "Super Saver" SATAjet 4000 B HVLP achieves particularly high transfer efficiency rates, due to its low pressure technology.

SATAjet® 4000 B RP (DIGITAL)

SATAjet® 4000 B RP (DIGITAL)

Lighter, improved handling, higher precision: the ergonomic design.

SATAjet 4000 B, due to its ergonomically formed gun handle, fits like a glove. We have reduced its weight by 15% compared to the previous model. In addition, we have lowered the center of gravity of the spray gun by a great deal for the benefit of the painter.

Improved control elements.

Flat spray control, the spray fan can be precisely adapted to the shape of the object. For safer and even more comfortable paint application.

Softer: the nozzle concept

The new nozzle concept of the SATAjet 4000 B has been enhanced to meet the requirements of modern paint systems. Providing a uniform and perfectly shaped spray fan, the material lays down softly and evenly. The noise level has been reduced by up to 50%. Highest color match precision, high gloss and uniform paint distribution ensure brilliant finishes at rapid application speed. The "Super Speed" SATAjet 4000 B RP with its optimized high pressure technology stands for maximum application speed.

SATAjet® 3000 B HVLP (DIGITAL)

SATAjet® 3000 B HVLP (DIGITAL)

Jetstream:

Newly developed nozzle concept for even higher color match precision and homogeneous material distribution Wide and even fan for higher work speed Perfect for the application of base- and clear coats Even better surface quality for spotless finish Finest material atomization Ensures excellent painting results

Countdown: VOC-Compliant Equipment

Suitable for all waterborne and solvent-based material Complies with all VOC regulations with regard to solvent reduction and material savings – for the sake of our environment Transfer efficiency rate > 65 % Low over spray atomization Switch to waterborne materials, switch to SATAjet 3000.

Chrome Fever: High-Brilliance Gun for Brilliant Results

Fully chrome-plated paint spray gun Chrome is wear-resistant and retains its value Chrome is corrosion-proof – even with waterborne materials Chrome is as valuable as gold – both visually and technically With its elegantly refined finish you will always make a brilliant appearance.

Chrome Finger: The Perfect Extension of your Own Hand

A well-balanced gun in state-of-the-art design Perfect ergonomics for fatigue-free work, e.g. optimized center of gravity, lower triggering forces Every step turns out just right: easy handling and operation CCS - for individual labeling, personalization.

SATAjet® 3000 K HVLP

SATAjet® 3000 K HVLP

◆ Highest profitability - SATA® HVLP technology ensures transfer efficiencies considerably above 65 % required by VOC legislation. As a result, this pressure-fed high performance gun not only helps protect the environment, but also saves lots of expensive paint (approx. 30 % compared to a conventional high pressure gun).

◆ Finest atomization and a top-class finish are ensured by the high air volume. The slight additional cost for compressed air (compared to a conventional high pressure gun) are considerably exceeded by material savings. Even with the latest generation of High Solid materials, excellent atomization quality is achieved

◆ The patented air circulation principle provides an especially homogeneous and soft fan. The large fan and high material flow rates ensure swift work .

◆ 100 % hand checked nozzle sets ensure the constantly high, well-known SATA quality - for complete guns as well as spare nozzle sets

◆ The durable air caps are made of brass (not of aluminum), therefore ensuring a long life time - a factor particularly important for industrial use. Nozzle sets ranging from 0.8 to 2.0 mean a wide field of application.

◆ Rapid air cap change with the SATA Quick Change System™ (only 1.5 turns) - ideal for continuous coating. The gun can be adapted without greater effort to existing work stations.

◆ Excellent handling - the short gun body, extremely low weight and the optimum balance ensure the gun "fits like a glove".

◆ Suitable for water-borne materials - paint needle and nozzle are made of stainless steel, and the nickel-plated gun body has been refined with a special coating.

◆ To make guns different from one another (i.e. guns for basecoat and guns for clearcoat), the gun can be marked by means of a coloured plastic disc (Colour Code System).

◆ Self-adjusting air and material packings with long life considerably reduce servicing efforts.

◆ The carefully polished nickel-plated gun surface and the Quick Change System reduce cleaning efforts as well.

◆ Naturally, the gun is equipped with a material flow control, a round / flat spray control and an air micrometer.

SATAjet® 1000 H™ RP®

SATAjet® 1000 H™ RP®

◆ Available with 1 l aluminum suction cup.

◆ Suitable for the application of noth waterborne and solvent-borne materials.

◆ Easy to clean and corrosion-resistant surface .

◆ Easy material refill due to quick release coupling on the cup .

◆ The QC Quick Change Thread allows an easy and quick air cap exchange with just one and a half turns.

◆ Robust and long-lasting.

SATAjet® 100 B F™ HVLP

SATAjet® 100 B F™ HVLP

◆ Highest economic efficiency - SATA’s HVLP technology guarantees transfer efficiency rates significantly above the required 65% by VOC legislation. This spray gun for filler and primer is not only environmentally friendly but it also saves a lot of material.

◆ Ergonomically optimized spray gun body in state-of-the-art design with small dimensions and low weight for fatigue-free working .

◆ Nozzles sizes ranging from 1.2 to 2.1 for primer and filler work

◆ 100% hand checked nozzle sets ensure the constant high SATA quality – for complete guns as well as spare nozzle sets Smoothly polished gun surface for easy and quick cleaning including material pas-sages .

◆ Now with material-flow control with counter nut and enhanced thread, as with the top coat spray guns.

◆ Air micrometer with graduations to adjust atomization air .

◆ Suitable for waterborne paints - paint needle and nozzle are made of stainless steel and the spray gun body has been carefully anodize.

◆ Self-adjusting air and material packings with a long lifetime significantly reduce the need for servicing .

◆ Comfortable trigger with low trigger-pull resistance and integrated paint needle cover, minimizing cleaning effort and increasing the life time of the needle packing.

◆ CCS-Clip (Colour Code System) to mark each spray gun individually .

◆ Single-handed round/flat control to adjust the spray pattern to the object which is to be painted .

◆ QCC quick cup connector for quick cup changes and fast cleaning.

SATAjet® 100 B F™ RP

SATAjet® 100 B F™ RP

◆ Ergonomically optimized spray gun body - in state-of-the-art design with small dimensions and low weight for fatigue-free working.

◆ Nozzles sizes ranging from 1.4 to 2.0 for primer and filler work.

◆ 100% hand checked nozzle sets ensure the constant high SATA quality – for complete guns as well as spare nozzle sets.

◆ Smoothly polished gun surface easy and quick cleaning including material pas-sages.

◆ Now with material-flow control with counter nut and enhanced thread, as with the top coat spray guns .

◆ Air micrometer with graduations to adjust atomization air .

◆ Suitable for waterborne paints - paint needle and nozzle are made of stainless steel and the spray gun body has been carefully anodized.

◆ Self-adjusting air and material packings with a long lifetime significantly reduce the need for servicing.

◆ Comfortable trigger with low trigger-pull resistance and integrated paint needle cover, minimizing cleaning effort and increasing the life time of the needle packing.

◆ CCS-Clip (Colour Code System) to mark each spray gun individually Single-handed round/flat control to adjust the spray pattern to the object which is to be painted.

◆ QCC quick cup connector for quick cup changes and fast cleaning.

SATAminijet® 3000 B HVLP

SATAminijet® 3000 B HVLP

◆ Highest profitability - SATA® HVLP technology ensures transfer efficiencies considerably above the 65 % required by VOC legislation. As a result, this miniature gun is extremely environmentally friendly.

◆ 9 different nozzle sizes - besides the standard nozzle sizes from 0.3 up to 1.1, from artistic, meticulous to more substantial design work, special "SR" nozzle sets in the sizes 0.8, 1.0 and 1.1 are available. Their atomization is specially adapted for small repair jobs (Spot / Smart Repair).

◆ 100 % hand checked nozzle sets ensure the constantly high, well- known SATA quality - for complete guns as well as spare nozzle sets.

◆ The durable air caps are made of brass (not of aluminum), therefore ensuring a long life time.

◆ Now with material-flow control with counter nut and enhanced thread, as with the top coat spray guns. Small and lightweight - to reach even the hardest accessible areas.

◆ Suitable for water-borne materials - paint needle and nozzle are made of stainless steel, and the chrome-plated gun body has been refined with a special coating. To make guns different from one another (i.e. guns for base coat and guns for clear coat), the gun can be marked by means of a coloured plastic disc (Colour Code System).

◆ Self-adjusting air and material packings with long life times considerably reduce servicing. The carefully polished chrome-plated gun surface reduces cleaning efforts.

◆ The infinitely variable round / flat spray control allows adapting the fan to all sorts of objects.

◆ Integrated air micrometer - helps you keep control over the Minijet just like a "big" one.

◆ anti-drip device integrated into the cup lid (only with plastic cups) reliably prevents material from emerging from the vent and dripping onto the painted surface.

SATAminijet® 3000 A™ HVLP

SATAminijet® 3000 A™ HVLP

◆ Highest profitability - SATA® HVLP technology ensures transfer efficiencies considerably above the 65 % required by VOC legislation.

◆ Finest atomization and a top-class finish are ensured by the high air volume. The slight additional cost for compressed air, compared to a conventional high pressure gun, are considerably exceeded by the material savings. Even with the latest generation of High Solid materials, excellent atomization quality is achieved.

◆ The patented air circulation principle provides an especially homogeneous and soft fan.

◆ The wide fan, high material flow rates and low weight allow swift work of the automatic system or robot.

◆ 100 % hand checked nozzle sets ensure consistently high, well-known SATA quality - for complete guns as well as spare nozzle sets.

◆ The durable air caps are made of brass (not of aluminum), therefore ensuring a long life time.

◆ Rapid air cap change with the SATA Quick Change System™ (only 1.5 turns). Suitable for water-borne materials - paint needle and nozzle are made of stainless steel, and the gun body features thorough anodizing.

◆ Self-adjusting air and material packings with long life times considerably reduce service efforts.

◆ The carefullyanodized gun surface and the Quick Change System reduce cleaning efforts as well.

◆ The infinitely variable round / flat spray control allows adjusting the fan to all sorts of objects.

SATAminijet® 100 B P

SATAminijet® 100 B P

◆ Fine atomization.

◆ Exact spray pattern distance.

◆ Less waste of time covering or sanding surfaces.

◆ Reduced weight.

◆ Small size.

◆ High ergonomics.

◆ Totally appropriate for waterborne paints.

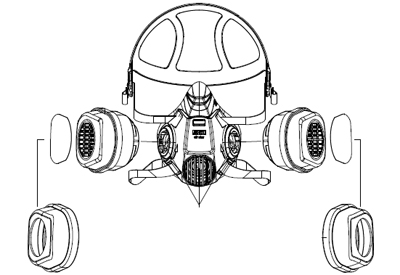

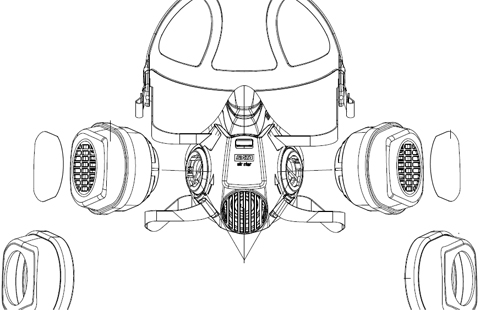

SATA AIR STAR F

SATA AIR STAR F

The Light Weight, anatomically shaped mask body is made of a dermatologically tested plastic/rubber mixture that fits any face shape perfectly. the area around the nose is very soft pliable for a snug fit and protects the painter form organic solvent vapor and over spray. the dual cartridge filter system ensures even weight distribution and a wide field of vision. inhalation resistance is low thanks to the filter's large surface area.

SATA AIR STAR WITH A2P3 D FILTER

Two universal combination filters provide reliable respiratory protection when working with solvent base or waterborne paint materials. the dual stage P2A3 D filter ensures the greatest possible degree of health protection up to thirty times the AGW/MAK value,i.e the limit in the work place/maximum workplace concentration.

COMFORTABLE SNUG FIT

COMFORTABLE SNUG FIT

The 4-point connection straps made of very soft material combined with the innovative X-shaped neck strap ensure a secure respirator fit in any workplace environment. The extra double-function neck strap allows the respirator to be lowered comfortably around the neck. that is particularly advantageous during short work breaks making it close at hand and ready for use.

HYGIENE BOX WITH FILTER TIMER

A Filter Timer is located on the SATA hygiene box that may be mounted on the wall. According to the time and type of respirator use, the recommended date to change filter cartridges may be indicated. Furthermore, the date of the next change of filter may be indicated accordingly. This makes control and maintenance easy for the SATA air star F half mask respirator.

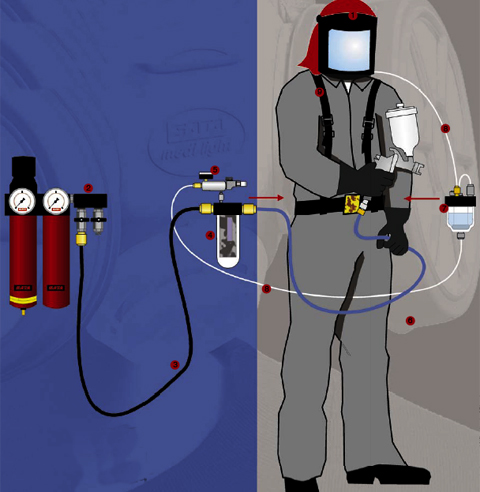

SATA® AIR STAR C™

SATA® AIR STAR C™

◆ Air supplied half mask for painters.

◆ Optimum health protection due to the supply of clean breathing air.

◆ Excellent fit for any type of facial contours.

◆ Very light and comfortable Suitable for workers who wear glasses.

◆ Innovative 4-point headband for more wearing comfort.

◆ No build-up of heat and moisture in the mask.

SATA VISION 2000

SATA VISION 2000

◆ Lightweight, comfortable breathing hood that thoroughly protects the face, hair and neck from over spray. It is also suitable for persons wearing glasses and persons with short beards or mustaches.

◆ Fresh air is supplied steadily through a silencer to the hood without drafts.

◆ The air supply has a variable adjustment according to the users requirements, while a shut-off system prevents airflow from being completely shut off.

◆ The compact activated charcoal filter is worn on the belt in a protective cage and removes oil vapor and gases. The level of filter saturation is indicated.

◆ A thin transparent visor sheet prevents reflections and distortion free vision. If the visor sheet becomes contaminated by over spray, it can be replaced quickly and easily.

◆ For reasons of hygiene, replacement of the hood lining and the sweatband is very easy.

◆ Obviously, the SATA respirator system is silicone-free, solvent resistant and electrically conductive.

◆ Protection up to 100 times the MWC value (maximum workplace concentration).

FINISH 250

FINISH 250

◆ Power : 1.1 kW (230 V)

◆ Maximum pressure : 250 bar

◆ Weight : 27 kg

◆ Delivery (120 bar): 1.25 l / min

◆ Max. nozzle size : 0.19"

FINISH 250 AIRCOAT

FINISH 250 AIRCOAT

◆ Power : 1.1 kW (230 V)

◆ Maximum pressure : 250 bar

◆ Weight : 27 kg

◆ Delivery (120 bar): 1.25 l / min

◆ Max. nozzle size : 0.19"

FINISH 270

FINISH 270

◆ Power : 1.1 kW (230 V)

◆ Maximum pressure : 250 bar

◆ Weight : 29 kg

◆ Delivery (120 bar): 1.65 l / min

◆ Max. nozzle size : 0.021"

FINISH 270 AIRCOAT PAINT

FINISH 270 AIRCOAT PAINT

◆ Power: 1.3 kW (230 V)

◆ Maximum pressure : 250 bar

◆ Weight : 29 kg

◆ Delivery (120 bar): 1.65 l / min

◆ Max. nozzle size: 0.021"

SUPER FINISH SF 21

SUPER FINISH SF 21

◆ Motor rating : 0.96 kW

◆ Voltage : 230 V / 50 Hz

◆ Weight: 26 kg

◆ Max. delivery : 1.7 l/min

◆ Max. nozzle size : 0.021"

SUPER FINISH SF 23

SUPER FINISH SF 23

◆ Motor rating : 1.3 kW

◆ Voltage : 230 V / 50 Hz

◆ Weight: 31 kg

◆ Max. delivery : 2.0 l/min

◆ Max. nozzle size : 0.023"

SUPER FINISH SF 27

SUPER FINISH SF 27

◆ Motor rating : 1.5 kW

◆ Voltage : 230 V / 50 Hz

◆ Weight: 40 kg

◆ Max. delivery : 2.5 l/min

◆ Max. nozzle size : 0.027"

SUPER FINISH SF 31

SUPER FINISH SF 31

◆ Motor rating : 1.7 kW

◆ Voltage : 230 V / 50 Hz

◆ Weight: 43 kg

◆ Max. delivery : 3.2 l/min

◆ Max. nozzle size : 0.031"

PROSPRAY PS 22

PROSPRAY PS 22

◆ Power : 0.85 kW (230 V)

◆ Voltage : 230 V / 50 Hz

◆ Weight: 14.5 kg

◆ Max. delivery : 1.9 l/min

◆ Max. nozzle size : 0.022"

PROSPRAY PS 24

PROSPRAY PS 24

◆ Motor rating : 1.1 kW

◆ Voltage : 230 V / 50 Hz

◆ Weight: 24.5 kg

◆ Max. delivery : 2.2 l/min

◆ Max. nozzle size : 0.024"

PROSPRAY PS 26

PROSPRAY PS 26

◆ Motor rating : 1.35 kW

◆ Voltage : 230 V / 50 Hz

◆ Weight: 29.5 kg

◆ Max. delivery : 2.7 l/min

◆ Max. nozzle size : 0.026"

PROSPRAY PS 34

PROSPRAY PS 34

◆ Motor rating : 1.8 kW

◆ Voltage : 230 V / 50 Hz

◆ Weight: 43 kg

◆ Max. delivery : 4.45 l/min

◆ Max. nozzle size : 0.034"

HEAVYCOAT HC 920 E

HEAVYCOAT HC 920 E

◆ Power : 3.1 kW (230 V)

◆ Max. pressure : 228 bar

◆ Weight: 83 kg

◆ Max. delivery : 5.5 l/min

◆ Delivery (120 bar) : 4.8 l/min

◆ Max. nozzle size : 1 gun 0.043"

HEAVYCOAT HC 920 G

◆ Power : 4 PS (Honda)

◆ Max. pressure : 228 bar

◆ Weight: 74 kg

◆ Max. delivery : 5.5 l/min

◆ Delivery (120 bar) : 5.0 l/min

◆ Max. nozzle size : 1 gun 0.043"

HEAVYCOAT HC 940 E (SSP)

HEAVYCOAT HC 940 E (SSP)

◆ Power : 3.1 kW (230 V)

◆ Max. pressure : 228 bar

◆ Weight: 83 kg (84.5 kg SSP)

◆ Max. delivery : 6.6 l/min

◆ Delivery (120 bar) : 5.2 l/min

◆ Max. nozzle size : 1 gun 0.052"

HEAVYCOAT HC 940 G (SSP)

◆ Power : 5.5 PS (Honda)

◆ Max. pressure : 228 bar

◆ Weight: 76 kg (77.5 kg SSP)

◆ Max. delivery : 8.0 l/min

◆ Delivery (120 bar) : 7.6 l/min

◆ Max. nozzle size : 1 gun 0.052"

HEAVYCOAT HC 960 E(SSP)

HEAVYCOAT HC 960 E(SSP)

◆ Power : 5.5 kW (400 V)

◆ Max. pressure : 228 bar

◆ Weight: 100 kg (101.5 kg SSP)

◆ Max. delivery : 10 l/min

◆ Delivery (120 bar) : 10 l/min

◆ Max. nozzle size : 1 gun 0.056"

HEAVYCOAT HC 960 G(SSP)

◆ Power : 8 PS (Honda)

◆ Max. pressure : 228 bar

◆ Weight: 88 kg (891.5 kg SSP)

◆ Max. delivery : 12 l/min

◆ Delivery (120 bar) : 11 l/min

◆ Max. nozzle size : 1 gun 0.056"

EVOMOTION 31-40AL

EVOMOTION 31-40AL

The piston pump is driven with compressed air. This compressed air moves up and down the air piston in the air motor (1) and thus also the pump piston in the material pump (6). After each stroke, the flow of compressed air is reversed through the reversing valve (9). Working materials are sucked in on the upward stroke and simultaneously conveyed to the gun in both strokes.

| DESCRIPTION | UNITS | 31-40 | 37-65 | 24-150 |

|---|---|---|---|---|

| Transmission Ratio | - | 31:1 | 37:1 | 24:1 |

| Flow volume per double stroke (DS) | cm³ cc |

40 | 65 | 150 |

| Max. operating pressure (Pump) | MPa bar psi |

24.8 248 3597 |

29.6 296 4292 |

19.2 192 2786 |

| Max. operating pressure (Spraypack) | MPa bar psi |

24.8 248 3597 |

25 250 3625 |

19.2 192 2786 |

| Max. possible strokes in operation | DH/min DS/min |

60 | 60 | 60 |

| Min. - Max. air inlet pressure | MPa bar psi |

0.2-0.8 2-8 28-116 |

0.2-0.8 2-8 28-116 |

0.2-0.8 2-8 28-116 |

| Ø air inlet connection (female) | Inch | G 3/8" | G 1/2" | G 1/2" |

| Min. Ø compressed air hose | mm Inch |

13 0.512 |

13 0.512 |

13 0.512 |

| Air consumption (at 0.6 MPa; 6 bar; 87 psi) per DS | nl scf |

8.9 0.31 |

15.7 0.54 |

19.9 0.70 |

| Sound pressure level at max. permissible air pressure* | dB(A) | 80.8 | 85.0 | 79.9 |

| Sound pressure level at 0.6 MPa; 6 bar; 87 psi air pressure* |

dB(A) | 77.4 | 81.6 | 76.1 |

| Sound pressure level at 0.4 MPa; |

dB(A) | 72.6 | 77.5 | 77.5 70.9 |

| Ø Piston of air motor | mm inch |

100 4.0 |

140 5.5 |

140 5.5 |

| Material inlet connection (female) | Inch | G 1/2" | G 1" | G 1" |

| Material outlet connection (female) (in case of Spraypack version M16x1.5) |

Inch | G 3/8" | G 3/8" | G 1/2" |

| Weight | kg lb |

18 39.6 |

35 77 |

47 103.5 |

| Max. material pressure at pump inlet | MPa bar psi |

2 20 90 |

| Range of material temperature | °C F |

+5° ÷ 80° (+41 ÷ +176) |

| Range of the ambient temperature | °C F |

+5° ÷ 60° (+41 ÷ +140) |

| Allowable sloping position at work | <) ° | ± 10 |

Besides the proved IceBreaker product line there is an additional new EvoMotion pump range. This pumps characterized themselves by a wide application spectrum and a complete range.

The benefits:

◆ Anti-pulsation technology

◆ Powerful and economical

◆ Working pressure (maximum operating pressure) of 112 to 450 bar

◆ Delivery rates (volumetric flow per double stroke) from 15 to 235 cc

| Intensification ratio | Volumetric flow per double stroke | Volume for 60 double strokes | Volume max. free outlet | Max. working pressure | Max. air inlet pressure | Air consumption at 6 bar per double stroke | Sound pressure level at max. permissible air pressure | Max. nozzle size at 150 bar |

|---|---|---|---|---|---|---|---|---|

| 75:1 | 150 cc 9.2 cin |

9 ltr/min 0.32 cfm |

30 ltr/min 1.06 cfm |

530 bar 7700 psi |

7.1 bar 103 psi |

80 nl 2.83 scft |

83 dB(A) | 0.035" |

| Intensification ratio | Volumetric flow per double stroke | Volume for 60 double strokes | Volume max. free outlet | Max. working pressure | Max. air inlet pressure | Air consumption at 6 bar per double stroke | Sound pressure level at max. permissible air pressure | Max. nozzle size at 150 bar |

|---|---|---|---|---|---|---|---|---|

| 18:1 | 350 cc 18.3 cin |

18 ltr/min 0.63 cfm |

50 ltr/min 1.77 cfm |

140 bar 2030 psi |

7.7 bar 112 psi |

37.3 nl 1.32 scft |

83 dB(A) | 0.052" |

| Intensification ratio | Volumetric flow per double stroke | Volume for 60 double strokes | Volume max. free outlet | Max. working pressure | Max. air inlet pressure | Air consumption at 6 bar per double stroke | Sound pressure level at max. permissible air pressure | Max. nozzle size at 150 bar |

|---|---|---|---|---|---|---|---|---|

| 35:1 | 70 cc 4.3 cin |

4.2 ltr/min 0.15 cfm |

35 ltr/min 1.24 cfm |

250 bar 3625 psi |

7.1 bar 103 psi |

18.6 nl 0.66 scft |

77 dB(A) | 0.021" |

| Intensification ratio | Volumetric flow per double stroke | Volume for 60 double strokes | Volume max. free outlet | Max. working pressure | Max. air inlet pressure | Air consumption at 6 bar per double stroke | Sound pressure level at max. permissible air pressure | Max. nozzle size at 150 bar |

|---|---|---|---|---|---|---|---|---|

| 15:1 | 150 cc 9.2 cin |

9 ltr/min 0.32cfm |

35 ltr/min 1.24 cfm |

120 bar 1740 psi |

8 bar 116 psi |

16.5 nl 0.59 scft |

77 dB(A) | 0.035" |

| Intensification ratio | Volumetric flow per double stroke | Volume for 60 double strokes | Volume max. free outlet | Max. working pressure | Max. air inlet pressure | Air consumption at 6 bar per double stroke | Sound pressure level at max. permissible air pressure | Max. nozzle size at 150 bar |

|---|---|---|---|---|---|---|---|---|

| 22:1 | 18 cc 1.09 cin |

1.08 ltr/min 0.04 cfm |

3.5 ltr/min 0.12 cfm |

176 bar 2552 psi |

8 bar 116 psi |

3 nl 0.11 scft |

80 dB(A) | 0.015" |