THE BOSS

THE BOSS

◆ Next-generation Super-automatic work station, suitable for fitting/removing all kinds of tires for passenger's cars and LCVs 10"-30" (max. tire diam. 1200 mm/47", max. tire width 410 mm./16"), equipped with new-design automatic finger-tool, to remove tire bead without using the traditional bead lifting lever.

THE QUEEN

THE QUEEN

SUPER-AUTOMATIC TOUCHLESS TIRE CHANGER

◆ Super automatic tyre changer without use of bead lifting lever, suitable for fitting/removing all kinds of passenger car and LCV tires from 10'' to 34'' (max. wheel diameter 1200 mm/47'', max wheel width 410 mm/16'').

◆ To the advantage of the user, the 220V motor is controlled by an innovative inverter capable of adapting to the stress encountered while mounting/demounting the tyre, causing the spindle to slow down automatically when necessary.

S 225 GT

S 225 GT

SUPERAUTOMATIC TYRE CHANGER, SUITABLE FOR CAR AND MOTORCYCLE WHEELS

◆ Superautomatic tyre changer, suitable for car and motorcycle wheels having rim size from 10" to 24" (max. diameter 1000mm./39", max. wheel width 390mm./15"). Equipped with turntable double_speed rotation system with pedal control.

S 112 F

S 112 F

SEMIAUTOMATIC TYRE CHANGER WITH SIDEWARDS MOVING ARM

◆ Semiautomatic tyre changer with sidewards moving arm, suitable for car and motorcycle wheels having rim size from 10" to 20" (max. diameter 1000mm/39”, max. wheel width 330 mm/13”).

S 551

S 551

UNIVERSAL TYRE CHANGER SUITABLE FOR ANY TRUCK AND HEAVY DUTY WHEEL

◆ Universal tyre changer suitable for any truck and heavy duty wheel with 14”-56” rim (max. diameter 2300 mm./90,5”, max. wheel width 1065 mm./42”). Equipped with two-speed chuck and movable control unit, for safety and convenience reasons.

S 554

S 554

TYRE CHANGER SUITABLE FOR ANY TRUCK AND HEAVY DUTY WHEELS

◆ Tyre changer suitable for any truck and heavy duty wheels having rim size from 14" - 26" (max. wheel diameter 1200 mm./47"; max. wheel width 780 mm./30,5"). Equipped with wheel centering hand system by flange and cones; also equipped with traditional double tool for mounting/removing tubeless and/or tube tyres.

SS 0010 Kompact 3

SS 0010 Kompact 3

◆ 1020 Kg of push at 8 Bar (1300 Kg at 10 Bar)

◆ Serial Lower Clamp

◆ Interconnected Arms

◆ 2 new hooks to spring block

◆ 3 flanges in pig-iron ticked off with teflon unscrape cover

◆ Conic spring adapter

◆ Swinging stand with place for flanges, hardened

◆ Dimensions Weight: 60x60x1560,60 Kg

Nitropoint 3

Nitropoint 3

◆ Nitorgen generators for cars, vans, dinghies and off-road vehicle

◆ Usable without external tank

◆ Suggested tank50/100 L

◆ Kitinflation - deflation gun and tube (in series)

◆ Contorl display pollution

◆ Kit air-stop

OPTIMA

OPTIMA

The OPTIMA wheel balancer utilizes 3 laser measurement units with CCD cameras that are integrated into the balancer. Since the surface of the rims in the market does vary from dark, dirty, black to shining chrome with a laser device only there would be problems in scanning several wheels. Combining the laser technology with CCD technology known from the aligners does solve this issue. The scanner components of the OPTIMA wheel balancer perform a variety of geometric measurements of the complete wheel assembly, the rim and the tire during shaft rotation. These measurements are interpreted by the wheel balancer’s on-board embedded PC to provide the features described in the previous slides and perform geometric matching to improve the wheel running conditions.

FEATURE

FEATURE

Electro-mechanical clamping device “power clamp” makes clamping of the wheel easy for the operator and always accurate for the measurement. The balancer “knows” if a wheel has been clamped and if it has been clamped properly since the clamping procedure is monitored by the internal processor. With the electro-mechanical design there is no need for an air supply at the OPTIMA wheel balancer and issues like air leaking gaskets etc. will never occur. Clamping errors are an issue of the past with the power clamp system.

Automatic wheel weight placement selection including the appropriate ALU mode makes the operation of the OPTIMA wheel balancer very simply. Out of this the operator does not need to take care.

◆ what kind of wheel he balances

◆ what wheel weight placement mode is to be used (clip - clip / ALU)

Non touch 3 D Imaging wheel profiling capability and automatic wheel weight placement mode selection (clip - clip / ALU) reduce possible mistakes done by the operator when wheel data are entered.

Non touch rim run out capability is very accurate and ensures that the real run out is measured. Measurement of run out with a laser device is the technology used by the tire manufacturers in the industrial applications. Since radial and lateral run out is measured also a wheel mounting error on the balancer can easily be detected.

Automatic split weight mode capability including spoke count and detection of spoke location makes the feature SPOKE an “easy to operate” feature for the operator. In the past the operator had to understand how to operate the SPOKE feature (enter the number of spokes and place a spoke on the 12 o´clock position to activate the spoke feature), now he simply pushes the F4 button to activate the split mode. The value for both stick on weights on the left side will be displayed immediately. Selling spoke placement as a service generates additional profit for the shop.

Thread depth indication TDI The TDI function gives an information to the user if the tread depth is OK, CRITICAL or BAD. The feature is realized in a way that it gives an indication only (in fact it measures the center of the tread and can detect regular wear only) and NOT a real value thus not requiring any additional cycle time.

Rim measurement (available from software 2.9) If a rim is clamped on geodyna optima and measurement started, the machine will recognise that it is a rim only and no tyre / wheel assembly and measure automatically radial run-out of both bead seats as well as lateral run-out of the rim. The test results are viewed on the screen and can be output on the printer. Two lines were added to the optima parameter screen.

Laser pointer feature to attach adhesive wheel weights on alloy rims makes mechanical gauge arm completely obsolete. The operator sees where to place the weight in the 5 o'clock position and does not have to watch the screen or listen to an audible signal while attaching the stick on weights.

GEODYNA OPTIMA

ART wheel weight removing tool, Accessory holder on left machine side, Non contact measurement of lateral and radial run-out, Automatic selection of wheel weight placement mode, Wheel weight location for stick-on weights (ALU program) taken from internal data base, Relocation of correction position via geodata measuring system with AutoStopSystem or via laser pointer in 5 o’clock position, Patented adhesive wheel weight clamp for geodata, Automatic counting of spokes and location of spoke positions for Behind-the-Spoke- Placement mode (HSP) through non contact devices, Electro-mechanical POWER CLAMP device for quick, convenient and safe clamping and mid-centering of wheels, VPM – Virtual plane measurement, Automatic orientation into correction planes, Cones 42–77 mm, 72–99 mm, 96–116 mm diameter, Spacer ring, clamping sleeve, clamping head.

GEODYNA 6800

15” VGA standard colour monitor, Rim disc light and mirror for quick and ergonomic operation ALU modes

Including geopac 2 accessory kit, consisting of universal weight pliers and adhesive weight removing tool , geodata measuring system with automatic data transfer (3D SAPE) and positioning of adhesive wheel weights, Adhesive wheel weight clamp, AutoStopSystem for the geodata gauge arm when in exact correction position, VPM – Virtual plane measurement, Compatible with – geodyna 6800 / 6800p, Automatic measurement of static and dynamic unbalance in a single measuring run, Automatic orientation into correction planes, Wheel modes: standard wheels, 15-deg taper, flat base and drop center rims, special rotors, motorcycle wheels, Balancing of car and light-truck wheels, 6 Balancing modes (5 for alloy wheels), 9 User profiles, Measuring time 3 seconds, HOS – Hofmann optimization mode, Minimization mode (matching), HSP – split weight mode, PAX wheel program.

GEODYNA 4900

◆ Virtual plane measurement (VPM) technique

◆ Automatic input of distance rim/machine, rim diameter and width (3D SAPE)

◆ 17" TFT flat screenAutomatic pre-selection of weight locations with the easyALU mode

◆ Hidden weight mode PAX wheel mode Automatic orientation of wheel into correction plane (12 h position)

◆ Optimization

◆ Gauge arm with weight clamp* and adhesive weight positioning system9 User profiles as a network capability

◆ Convenient on-line user guidance

◆ Comprehensive on-line help in more than 20 languages

GEODYNA 4500

◆ Virtual plane measurement (VPM) technique

◆ Automatic input of distance rim/machine and rim diameter (2D SAPE)

◆ Input of rim width by pressing of the function key and turning of the wheel*

◆ Conspicuous LC display

◆ Optimization

◆ Automatic pre-selection of weight locations with the easyALU mode

◆ Hidden weight mode

◆ PAX wheel mode

◆ Automatic braking of the wheel after measurement

◆ Pedal-operated main shaft lock

◆ Optimization

◆ Gauge arm with wheel weight clamp* and adhesive weight positioning system

◆ Conspicuous weight tray

◆ 4 User profiles

GEODYNA 980L

Geodyna 980L adds to tire tread life with its 2-Plane/Dynamic, off-the-vehicle balancing of truck tires. A pneumatic wheel lift is standard on the geodyna 980L, so heavy lifting is eliminated and proper wheel mounting is guaranteed. Users are assured accuracy with semi-automatic entries of wheel distance and diameter, along with easy re-calibration that saves on costly service calls. The geodyna 980L comes standard with mounting adapters for both hub-piloted and stud-piloted truck wheels. As a bonus, the geodyna 980L also comes with a passenger/light truck centering cone kit for automotive use.

GEOLINER 670/680

◆ Tall camera beam support(s) (1.8 m)

◆ 1 PC with Geo Pro 32 Bit software, vehicle specs, HDD, CD / DVD drive, floppy drive 3.5”, optical mouse, USB 2.0 interface, network card

◆ Operating system and keyboard, 19” Monitor

◆ 1 Remote control unit

◆ 1 Speaker assembly

◆ 4 Targets (2 x front end, 2 x rear end)

◆ 1 Mechanical wheel chock unit

◆ 1 Camera beam left/right with CCD camera system

◆ 1 A4 colour printer with data lead

◆ 1 Steering wheel holder

◆ 1 Brake pedal depressor

◆ 1 Mobile cabinet

GEOLINER 550

◆ Mobile terminal with drawer for printer and compartment for PC plus additional storage space; 17" monitor

◆ PC with Windows operating software and standard user software

◆ Set of 2 targets and 2 PODs with magnesium wheel clamps 11"-22"

◆ Complete and up-to-date OEM specs

◆ Measurement screen with all relevant data

◆ Can be used in different wheel alignment bays)

◆ Cordless communication via Bluetooth

◆ Long-life lithium-ion batteries

◆ No need for spoiler adaptor

◆ Easy to service

◆ Ride height modified vehicle specifications

◆ A-arm adjustment>

◆ Standard accessories: Steering wheel holder, brake pedal depressor

GEOLINER 480

◆ Windows® operating system

◆ 32 Bit Professional software with enhanced features and more convenient operation

◆ 8-sensor CCD camera technique

◆ Vehicle database

◆ Setting aids with animated graphics

◆ Customer database

◆ One-man operator guidance

◆ Hard disc drive for direct inputs

◆ Measurement and alignment of cradle

◆ Simultaneous reading of caster, camber and toe on the monitor

◆ Measurement of toe-out on turns and max. steering angle with mechanical, or electronic turntables(optional)

◆ Ink-jet colour printer A4

◆ Power supply 230 V, 50/60 H

◆ Compatible to ASA network

◆ CE - conform

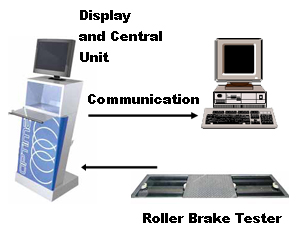

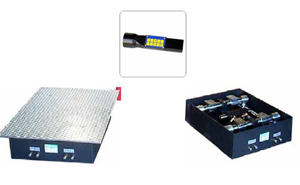

LIGHT VEHICLE ROLLER BRAKE TESTER SIMPLE

LIGHT VEHICLE ROLLER BRAKE TESTER SIMPLE

Heavy duty roller brake tester for passenger cars, vans and light commercial vehicles. In addition to measuring the brake forces per wheel and the difference between the left and right sides, the operator can determine the important quantities rolling resistance, actuation force, ovality (out-of-roundness) and brake fading for each wheel. Special attention has been given to prevent damage to the tires. The rollers are very quickly stopped when slippage occurs, even during the start-up of the motors. All roller brake testers are equipped with reliable worm gear motors. All moving components are supported by roller bearings for a long and trouble free service. The chassis is hot dip galvanised. With his weighing facility, the deceleration (brake efficiency) of the vehicle will be calculated and can compared with legal requirements for the service-, parking- and the emergency brake systems.

LIGHT VEHICLE SUSPENSION TESTER

The test equipment is build around 2 plates (1 per wheel) which are shacked with a modulated frequency with a fixed range. The test equipment records during all along the test the dynamic force for each wheel. The measurement precept is EUSAMA based (European Shock Absorbers Manufacturer’s). Efficacy and dis symmetry are obtained by measurement of static and dynamic stand on force and dynamic The test is preceded on both wheels in the same time.

LIGHT VEHICLE SIDE SLIP TESTER

Side slip meter with software relaxation tool for better accuracy and repeatability. The sideslip meter tests for tire wear and determines if the wheel alignment needs to be checked. It indicates how much the tire is being dragged sideways and gives a fast indication of the effective dynamic toe. Software compensation relieves any built-up tire forces which would impair the measurement. Also available as an option is the mechanical relaxation plate. This device is linked to the brake tester.

LIGHT VEHICLE JOIN PLAY DETECTOR

The Car Play Detector is designed to check quickly and efficiently most steering and suspension components. Without the help of a second person, it enables a technician quickly to detect play and wear in the wheel guiding and steering parts of passenger cars and light trucks. A used car often shows wear and tear in ball joints, bushings, fixations, pivot points, link bolts and shock absorber mountings. Most worn or damaged components can be identified before they pose problems. A Play Detector is also called Clearance Detector or Wear Detector Plates. The equipment movements simulate the road forces that act on the suspension and steering components in a turn. The play in the components is visually checked with the low-voltage control lamp. Two switches on the lamp control the movements of the plates. Just one person can easily operate the tester. The model can be installed on both sides of an inspection pit. The units are air-powered and require standard mains supply for the control box and the inspection lamp.

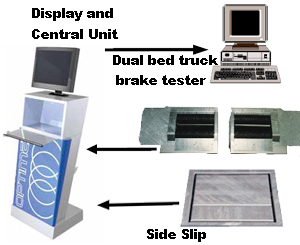

TRUCK ROLLER BRAKE TESTER

TRUCK ROLLER BRAKE TESTER

The truck roller brake tester is a dual roller bed and can therefore be installed on the left and right side of an inspection pit. Both the brake forces as well as the difference left/right of an axle are clearly presented on the monitor display. The operator can determine important quantities like rolling resistance, actuation force, ovality (out-of-roundness) and brake fading for each wheel. The equipment is standard equipped with automatic slip detection. Even with the heaviest loaded axle, it causes no problems to drive out of the rollers. The chassis is fully galvanized and all moving components are equipped with quality bearings. This reduces the maintenance on the brake tester to a minimum.

With this weighing facility, the deceleration (brake efficiency) of the vehicle will be calculated and can be compared with legal requirements for the service-, parking- and the emergency brake systems.

TRUCK SIDE SLIP TESTER

Side slip meter with software relaxation tool for better accuracy and repeatability. The side slip meter tests for tire wear and determines if the wheel alignment needs to be

checked. It indicates how much the tire is being dragged sideways and gives a fast indication of the effective dynamic toe.

TRUCK JOIN PLAY TESTER

TRUCK JOIN PLAY TESTER

This equipment is an electronic hydraulic play detector for trucks and is designed to check quickly and efficiently most steering and suspension components. Without the help of a second person, it lets a technician quickly detect play and wear in the wheel guiding and steering parts of trucks. This equipment consists of a control unit, a low voltage control lamp and two platforms, each with a hot dip galvanised chequered plate. A set of floor frames is optional.

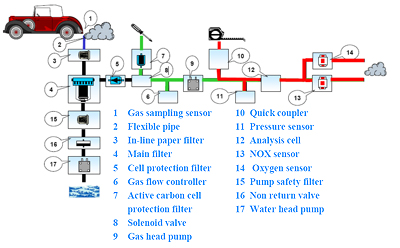

GAS ANALYSER / SMOKE METER

GAS ANALYSER / SMOKE METER

ULTIMAX is a Diagnostics tool:

ULTIMAX 600 units have an integrated EOBD data read-out unit with the following functions:

Read-out of engine parameters (RPM, temperatures, pressure readings, etc.)

◆ Read-out and printout of error codes with plain text display of error cause

◆ Read-out of engine parameters when errors occur, code deletion

◆ Read-out and start-up of tests for exhaust gas system (catalytic converter, EGR, Ignition, lambda probe, etc.)

Gas analyzer for gasoline engine: ULTIMAX 60x

The Gas analyzer and smoke meter are in accordance with the very last and accurate international regulation. So since the product launch, the equipment is OIML class 0 and ISO 3930 class 0 fully compatible.

Diesel smoke meter for Diesel engine : ULTIMAX 66x

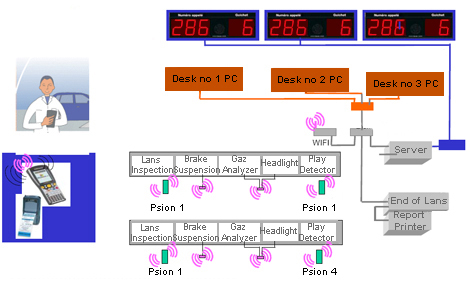

In order to make the customer life easy , a queuing system has to provide a global system to arrange customer visit and organize the service which has to be provided to him with no effort for him to known how this will be assumed.

So from the Welcome Point to the final desk, the queuing system gather the information from the customer , provided them to the system, and the customer is kept inform about his status demand through the various display available every where in the building.

A complete module will be linked to the actual the lane management . This module will be composed of 3 majors parts :

◆ The welcome point

◆ The queuing management

◆ The display solution.

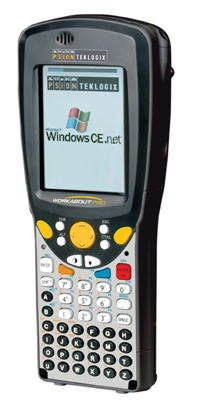

The welcome point solution has to be hand held system based.

The Hand held terminal: - Workabout (Back and white) (WIFI based)

◆ Wireless communication : WiFi 802.11b, GSM/GPRS and Bluetooth

◆ OS Windows CE .NET 4.2

◆ 58 key back light Keyboard - 1/4 VGA large screen

◆ Passive tip or finger tip action

◆ included option : 2D Bar code reader

◆ included option : handle.

The printer:

◆ Hand held printer

◆ Wifi interface

The QL 320 is Zebra's time-tested direct thermal mobile printer. It has been used in thousands of indoor and outdoor applications, including price marking, shelf labeling.

| DESCRIPTION DISPLAY | TICKET DIGIT | DESK DIGIT | DIGIT HEIGHT | VISIBILITY | COLOR | PHYSICAL CHARACTERISTICS | LOAD SPEAKER | INTERFACE | SUPPLY |

|---|---|---|---|---|---|---|---|---|---|

| Specification | 3 | 2 | 135 mm | 60/65 m | Red | 700 x 235 x 37 mm | Included (music at each call) | RS485 | 220 V |

E-07-OPS

◆ Adjustable over pressure setting (OPS)

◆ Auto-start inflation

◆ Automatic zero drift adjustment

◆ Remain at last setting

◆ Comprehensive diagnostics and error reporting

◆ Audible and visual end of the cycle signal indicators

◆ Large backlight LCD display

◆ Vandal resistant mechanical switches

◆ Suits Standard nitrogen bottle / Direct nitrogen supply from generator / Air compressor

◆ 1 Nos.*10M/32.8ft standard hose with single clip-on open type chuck

Dimensions(Height*Width*Depth) : 290mm*230mm*120mm 11.4"*9.1"*4.7"

Net Weight : 4 kg/8.8 lbs

Gross Weight : 6.5 kg/14.3 lbs

Packing Size (Height*Weight*Depth) : 170mm*500mm*290mm 6.7"*19.7"*11.4"

Power Requirement : 100-240 Vac 50/60 HZ

Power Consumption : 10VA

Operating Temperature Range : -20°C / -4°F to 70°C / 158°F

Max Inlet Air/Nitrogen Supply : 145 PSI / 10 bar / 1000 kPA

Operating range : 5-102 PSI / 0.3-7 bar / 35-700 kPa

Over Pressure Setting Range : 0-29 PSI / 0-2.0 bar / 0-200 kPa

Accuracy : ±1 PSI / 0.07 bar / 7 kPa

Resolution : 1 PSI / 0.1 bar / 5 kPa

Units of Measurement : PSI / bar / kPa

E-0124-OPS

◆ Adjustable over pressure setting (OPS)

◆ 4 air outlets allow simultaneous inflation of up to 4 tyres

◆ Auto-start inflation

◆ Automatic zero drift adjustment

◆ Remain at last setting

◆ Comprehensive diagnostics and error reporting

◆ Audible and visual end of the cycle signal indicators

◆ Large backlight LCD display

◆ Vandal resistant mechanical switches

◆ Suites standard nitrogen bottle / Direct nitrogen supply from generator / Air compressor

◆ 4 Nos.*10M/32.8ft standard hoses with single clip-on closed chuck

Dimensions (Height*Width*Depth) : 510mm*230mm*120mm 20.1"*9.1"*4.7"

Net Weight : 6 kg / 13.2 lbs

Gross Weight : 14.5 kg / 32 lbs

Packing Size (Height*Weight*Depth) : 200mm*580mm*480mm 7.9"*22.8"*18.9"

Power Requirement : 100-240 Vac 50/60 HZ

Power Consumption : 23VA

Operating Temperature Range : -20°C / -4°F to 70°C / 158°F

Max Inlet Air/Nitrogen Supply : 217 PSI / 15 bar / 1500 kPa

Operating range : 5-174PSI / 0.3-12 bar / 35-1200 kPa

Over Pressure Setting Range : 0-29 PSI / 0-2.0 bar / 0-200 kPa

Accuracy : ±1 PSI / 0.07 bar / 7 kPa

Resolution : 1PSI/0.1 bar / 5 kPa

Units of Measurement : PSI / bar / kPa

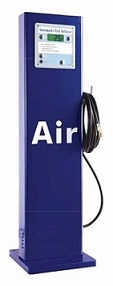

E-012-OD

◆ Auto-start inflation

◆ Automatic zero drift adjustment

◆ Remain at last setting

◆ Comprehensive diagnostics and error reporting

◆ Audible and visual end of the cycle signal indicators

◆ Large backlight LCD display

◆ Vandal resistant mechanical switches

◆ Suits standard nitrogen bottle/Direct nitrogen supply from generator/Air compressor

◆ 1 Nos.*10M/32.8ft standard hose with single clip-on open type chuck

Dimensions (Height*Width*Depth) : 1260mm*360mm*360mm 49.6"*14.2"*14.2"

Net Weight : 17.5 kg / 38.6 lbs

Gross Weight : 21 kg / 44.6 lbs

Packing Size (Height*Weight*Depth) : 200mm*1290mm*400mm 7.9"*50.8"*15.7"

Power Requirement : 100-240 Vac 50/60 HZ

Operating Temperature Range : -20°C / -4°F to 70°C /1 58°F

Max Inlet Air/Nitrogen Supply : 217 PSI / 15bar / 1500 kPa

Operating range : 5-174 PSI / 0.3-12 bar / 35-1200 kPa

Accuracy : ±1 PSI / 0.07 bar / 7kPa

Resolution : 1PSI / 0.1bar / 5kPa

Units of Measurement : PSI / bar / kPa

E-1135

◆ Generates nitrogen from your compressed air

◆ Auto Shut-off

◆ 2 Pre-Filters

◆ 50L/13.2gal (us) internal nitrogen storage tank

◆ 1 Nos.*10m/32.8ft standard hose with 2 quick couplers to connect the unit and your inflation gun

◆ Nitrogen purity test port

Dimensions (Height*Width*Depth) : 1255mm*700mm*435mm 49.4"*27.6"*17.1"

Net Weight : 87 kg / 191.8 lbs

Gross Weight : 104 kg / 229.3 lbs

Packing Size (Height*Weight*Depth) : 1380mm*730mm*510mm 54.3"*28.7"*20.1"

Power Requirement : 100-240 Vac 50/60 HZ

Power Consumption : 20VA

Operating Temperature Range : -20°C / -4°F to 70° / 158°F

Compressed Air Input Range : 87-123 PSI / 6-8.5 bar / 600-850 kPa

Compressed Air Input Flow : 250L/min (8.0cfm)

Nitrogen Purity : 95-99+%

Nitrogen Output : 50L/min (1.8 cfm) @ 116 PSI / 8 bar / 800 kPa Absorption pressure

Maximum Nitrogen Pressure in Tank : 102 PSI / 7 bar / 700 kPa

E-1135-N2P

◆ Generates nitrogen from your compressed air

◆ 2 Pre-Filters

◆ 50L/13.2gal (us) internal storage tank

◆ Auto-start inflation

◆ Automatic zero drift adjustment

◆ Remain at last setting

◆ Audible and visual end of the cycle signal indicators

◆ Self-diagnostic features

◆ Vandal resistant mechanical switches

◆ Large backlight LCD display

◆ 1 Nos.*10M/32.8ft standard hose with single clip-on open type chuck

◆ Comprehensive diagnostics and error reporting

◆ Nitrogen purge and fill cycle (N2P)

◆ Nitrogen purity test port

◆ Adjustable over pressure setting (OPS)

◆ Adjustable number of cycles

◆ Adjustable lower purge pressure limit

◆ Auto Shut-off

◆ 1Nos Nitrogen Outlet to connect the unit and your tyre inflation gun

Dimensions (Height*Width*Depth) : 1255mm*720mm*435mm 49.4"*28.3"*17.1"

Net Weight : 89 kg / 196.2 lbs

Gross Weight : 106 kg / 233.7 lbs

Packing Size (Height*Weight*Depth) : 1380mm*730mm*510mm 54.3"*28.7"*20.1"

Power Requirement : 100-240 Vac 50/60 HZ

Power Consumption : 30VA

Operating Temperature Range : -20°C / -4°F to 70°C / 158°F

Compressed Air Input Range : 87-123 PSI / 6-8.5 bar / 600-850 kPa

Compressed Air Input Flow : 250L/min (8.0cfm)

Nitrogen Purity : 95-99+%

Nitrogen Output : 58L/min (2.0cfm) @116 PSI / 8 bar / 800 kPa Absorption pressure

Operating Range : 5-90 PSI / 0.3-6.2 bar / 35-620 kPa

Resolution : 1 PSI / 0.1 bar / 5 kPa

Units of Measurement : PSI/bar/kPa

E-1135B-N2P

◆ Generates nitrogen from your compressed air

◆ 1 Pre-Filters

◆ Internal nitrogen storage tank

◆ Auto-start inflation

◆ Automatic zero drift adjustment

◆ Remain at last setting

◆ Audible and visual end of the cycle signal indicators

◆ Self-diagnostic features

◆ Vandal resistant mechanical switches

◆ Large backlight LCD display

◆ 2 Nos.*8M/26ft standard hoses with single clip-on closed chuck

◆ Comprehensive diagnostics and error reporting

◆ Nitrogen purge and fill cycle (N2P)

◆ Nitrogen purity test port

◆ Adjustable over pressure setting (OPS)

◆ Adjustable number of cycles

◆ Adjustable lower purge pressure limit

◆ 2 air outlets allow simulataneous inflation of up to 2 tyres

◆ 1Nos Nitrogen Outlet to connect the unit and your tyre inflation gun

Dimensions (Height*Width*Depth) : 1260mm*450mm*590mm 49.6"*17.7"*23.2"

Net Weight : 72 kg / 159 lbs

Gross Weight : 89 kg / 196 lbs

Packing Size (Height*Weight*Depth) : 1380mm*730mm*510mm 54.3"*28.7"*20.1"

Power Requirement : 100-240 Vac 50/60 HZ

Power Consumption : 30VA

Operating Temperature Range : -20°C / -4°F to 70°C / 158°F

Compressed Air Input Range : 87-217 PSI / 6-15 bar / 600-1500 kPa

Compressed Air Input Flow : 250L/min (8.0cfm)

Nitrogen Purity : 95-99+%

Nitrogen Output : 61L/min (2.1cfm) @ 116 PSI / 8 bar / 800 kPa Absorption Pressure

Maximum Nitrogen Pressure in Tank : 102 PSI / 7 bar / 700 kPa

Operating Range : 5-90 PSI / 0.3-6.2 bar / 35-620 kPa

Resolution : 1 PSI / 0.1 bar / 5 kPa

Units of Measurement : PSI/bar/kPa

E-1170

◆ Generates nitrogen from your compressed air

◆ Auto Shut-Off

◆ 2 Pre-Filters

◆ 118L/31.1gal (us) internal storage tank

◆ 1Nos*10m/32.8ft standard hose with 2 quick couplers to connect the unit and your tire inflation gun

◆ Nitrogen purity test port

Dimensions : Main Body | Tank

Height : 1310mm / 51.6" | 1100mm / 43.3"

Width : 730mm / 28.7" | 400mm / 15.7"

Depth : 620mm / 24.4" | 400mm / 15.7"

Net Weight : 167kg / 368.2lbs | 38kg / 83.8lbs

Gross Weight : 200kg/441.2lbs | 42kg/92.6lbs

Packing Size : Main Body | Tank

Height : 1450mm / 57.1" | 1180mm / 46.5"

Width : 730mm / 28.7" | 440mm / 17.3"

Depth : 670mm / 26.4" | 440mm / 17.3"

Power Requirement : 100Vac /240Vac 50/60HZ

Power Consumption : 45VA

Operating Temperature Range : -20°C / -4°F to 70°C / 158°F

Compressed Air Input Flow : 1100L/min (39cfm)

Nitrogen Purity : 95-99+%

Nitrogen Output : 228L/min (8cfm) @ 116 PSI / 8bar/ 800 kPa Absorption pressure

Maximum Nitrogen Pressure in Tank : 145-174 PSI / 10-12 bar / 1000-1200 kPa Adjustable

E-1170-N2P

◆ Generates nitrogen from your compressed air

◆ 2 Pre-Filters

◆ 118L/31.1gal (us) external nitrogen storage tank

◆ Auto-start inflation

◆ Automatic zero drift adjustment

◆ Remain at last setting

◆ Audible and visual end of the cycle signal indicators

◆ Self-diagnostic features

◆ Vandal resistant mechanical switches

◆ Large backlight LCD display

◆ 4 Nos.*8M/26ft standard hoses with single clip-on closed chuck

◆ Comprehensive diagnostics and error reporting

◆ Nitrogen purge and fill cycle (N2P)

◆ Nitrogen purity test port

◆ Adjustable over pressure setting (OPS)

◆ Adjustable number of cycles

◆ Adjustable lower purge pressure limit

◆ 6 air outlets allow simultaneous inflation of up to 6 tyres

◆ Auto Shut-Off

◆ 1Nos Nitrogen Outlet to connect the unit and your tyre inflation gun

Dimensions : Main Body | Tank

Height : 1310mm / 51.6" | 1100mm / 43.3"

Width : 730mm / 28.7" | 400mm / 15.7"

Depth : 620mm / 24.4" | 400mm / 15.7"

Net Weight : 170 kg / 374.8 lbs | 38 kg / 83.3 lbs

Gross Weight : 2207 kg / 456.4 lbs | 42kg/92.6lbs

Packing Size : Main Body | Tank

Height : 1450mm / 57.1" | 1180mm / 46.5"

Width : 730mm / 28.7" | 440mm / 17.3"

Depth : 670mm / 26.4" | 440mm / 17.3"

Power Requirement : 100Vac/240Vac 50/60HZ

Power Consumption : 70VA

Operating Temperature Range : -20°C / -4°F to 70°C / 158°F

Compressed Air Input Range : 145-217 PSI / 10-15 bar / 1000-1500 kPa

Compressed Air Input Flow : 1100L/min (39.0cfm)

Nitrogen Purity : 95-99+%

Nitrogen Output : 228L/min (8cfm) @ 116 PSI / 8 bar / 800 kPa Absorption Pressur

Maximum Nitrogen Pressure in Tank : 145-174 PSI / 10-12 bar / 1000-1200 kPa Adjustable

Operating Rang : 5-162 PSI / 0.3-11.2 bar / 35-1120 kPa

Over Pressure Setting Range : 0-29 PSI / 0-2.0 bar / 0-200 kPa

Nitrogen Purges : 0-9

Inflator Accuracy : ±1 PSI / 0.07 bar /7 kPa

Resolution : 1 PSI / 0.1 bar / 5 kPa

Units of Measurement : PSI/bar/kPa